Six Star Hardmetal are Chinese few can produce the very little carbide ball for ballpoint tips manufacturers.We take 'more professional, faster and honest ' as the spirit, and try our best to offer products with high quality and excellent service for every customer.

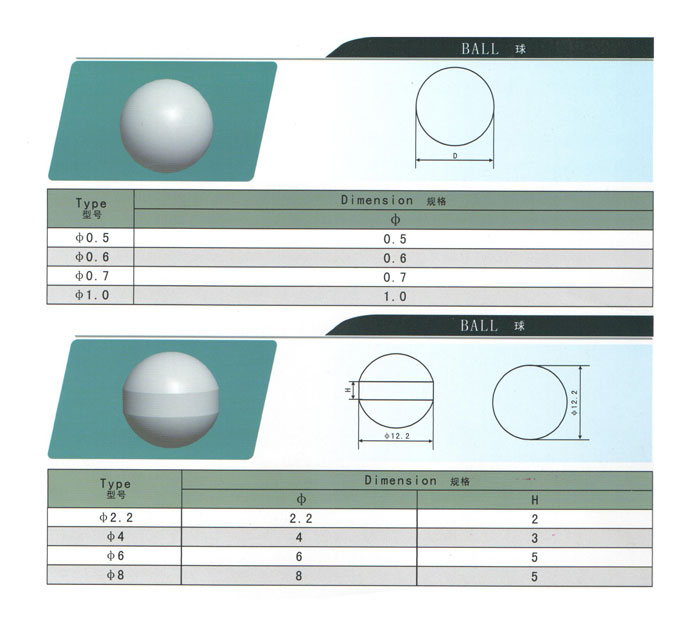

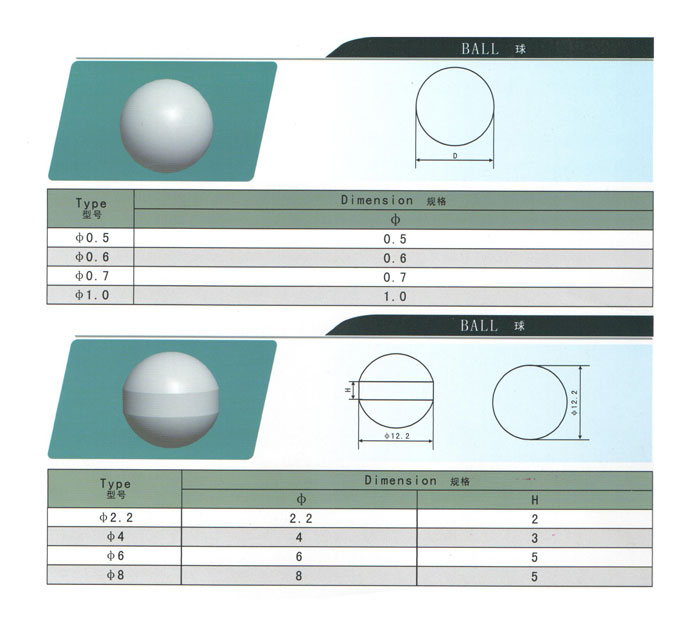

Types: Blanks and Polishing.(Tungsten Carbide Balls)

Recommended Grade: YG6 YG6X YG8 etc.

Tungsten Carbide ball is made by a refractory metal WC and a cemented metal Co or Ni for bonding together, and then molding, and high temperature for sintering to a ball. The company's production of cemented carbide ball is in all of the original raw materials. Production of ball has the following advantages: Small porosity, high hardness, anti-acid and anti-alkali corrosion, specifications between 2.5mm and 76.2MM. The Grades are tungsten-cobalt alloy ball YG6, YG6X, YG8, YG10, YG15, tungsten nickel alloy ball YN6, YN8. It Is widely used in a variety of hard alloy plant in high-precision alloy ball, grinding, abrasive, chemical, oil, etc.

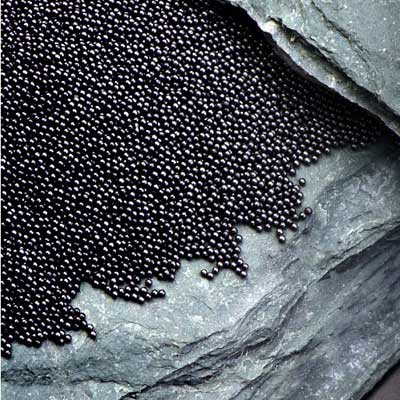

Tungsten carbide pellets are made of sintered tungsten carbide with a cobalt binder. We supply customers with tungsten carbide pellets which are available in sizes that vary from 4 mesh to 60 mesh specifications.

Consistent pellet size allows for maximum pellet density for uniform wear while affording maximum toughness.

Applications for carbide pellets include but are not limited to

· Hardbanding new and used drill pipe collars

· Buildup of oil field drill bits

· Welded in steel substrate in various wear resistant applications

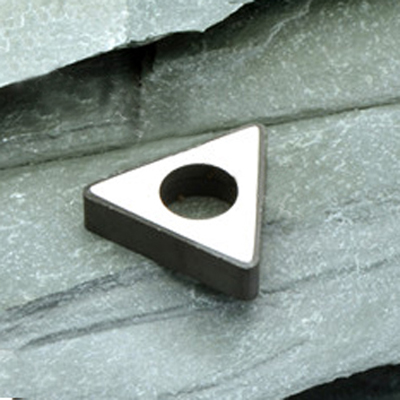

The component of YG6(Tungsten Carbide Balls):

Applications: YG6 carbide balls is widely used in a variety of hardware industry, valves, bearings, die-casting, punching parts, grinding, measuring.

Features: The main components are tungsten-cobalt alloy (WC-CO) with a high hardness, HRA90-92, abrasion resistance is better, its wear resistance is hundreds time previous to steel balls

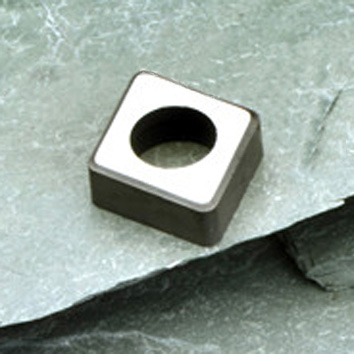

The component of YG6X(tungsten carbide ball):

Applications: YG6X carbide balls is widely used in a variety of hardware industry, valves, bearings, die-casting, punching parts, grinding, measuring, chemical, petroleum, and military.

Features: The main components are tungsten-cobalt alloy (WC-CO) with a high hardness it is a fine-grained alloy. It's hardness and wear resistance is a little better than YG6X alloy balls, but it's toughness is slightly lower than the ball of YG8, so it is suitable for production of wear-resistant alloy and Impact-resistant parts

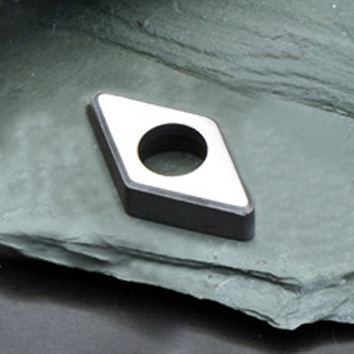

The component of YG8(carbide balls):

Applications: YG8 carbide is widely used in ball valves, bearings, die-casting, punching parts, grinding, measuring, hardness tester, petroleum, chemical, aviation and aerospace.

Features: The main components are tungsten-cobalt alloy (WC-CO) with a high hardness and wear resistance, it's toughness is better than YG6 alloy ball and has good anti-vibration shock engaged in the performance, suitable for production of strong shock and vibration components

The unlisted Sizes and Grades are available for your requirements!

print

print close

close